Man

vs.

machine

The Prize? Strawberries.

Photos for The Washington Post

Story, reporting and excerpts by Danielle Paquette.

Both human and machine have 10 seconds per plant. They must find the ripe strawberries in the leaves, gently twist them off the stems and tuck them into a plastic clamshell. Repeat, repeat, repeat, before the fruit spoils.

One February afternoon, they work about an acre apart on a farm the size of 454 football fields: dozens of pickers collecting produce the way people have for centuries —

and a robot that engineers say could replace most of them as soon as next year.

One Harv, seen above surrounded by potential investors, is programmed to do the work of 30 people. The machine hovers over a dozen rows of plants at the same time, picking five strawberries every second and covering eight acres a day.

Under the chassis 16 smaller steel robots scoop up strawberries with spinning, claw-like fingers, guided by camera eyes and flashing lights. Engineers compare them to duck feet, paddling furiously below the surface.

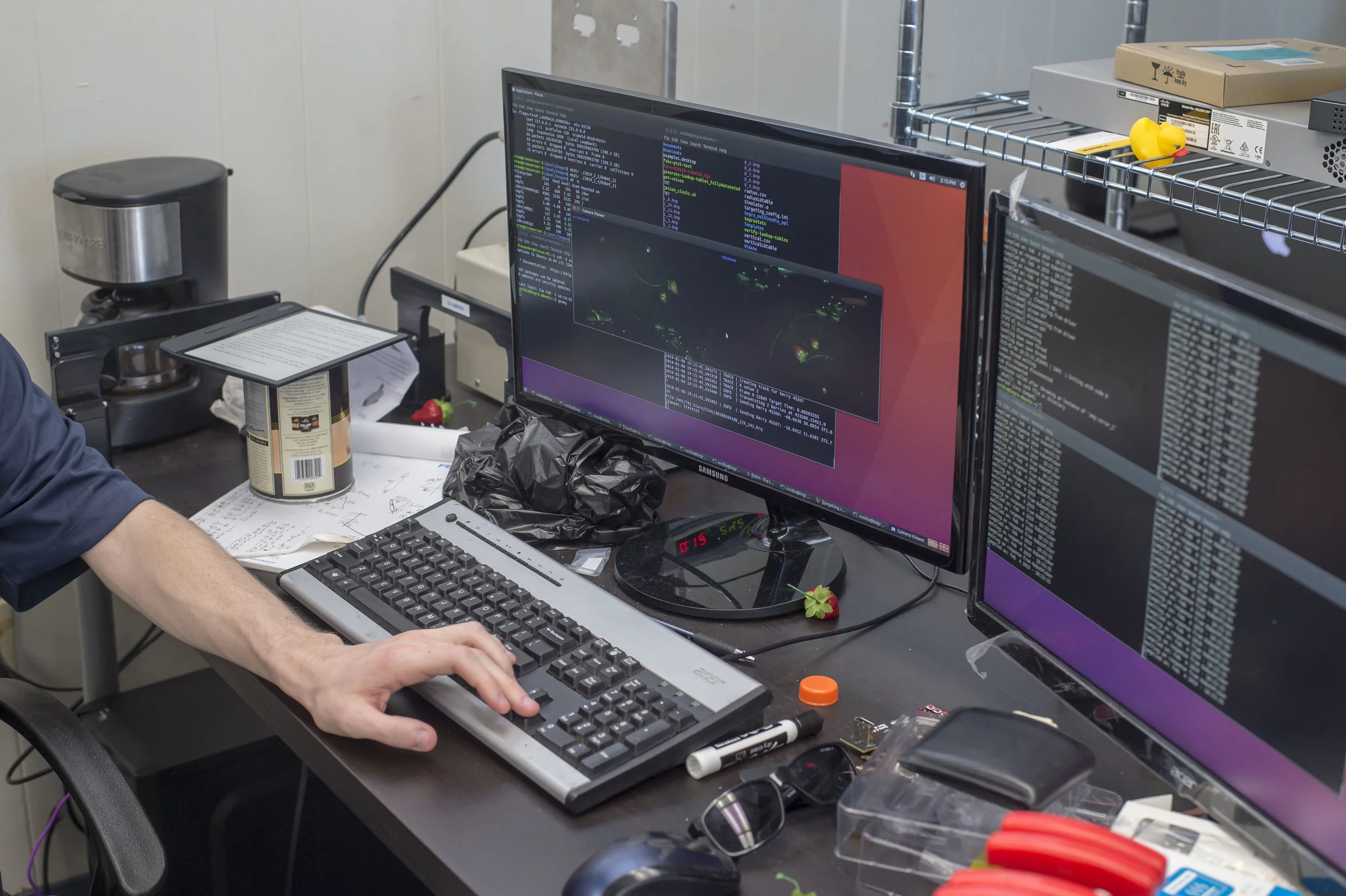

Behind the crowd of farmers and investors, a team of engineers watch the spectacle on a flat-screen TV inside a white trailer, their makeshift command center. Cameras inside Harv give them a close-up.

“It doesn’t care if it’s a Sunday or a holiday, the machine will work regardless.” - Doug Carrigan, farmer